Alco System Proves Hot Option For Cooking Applications

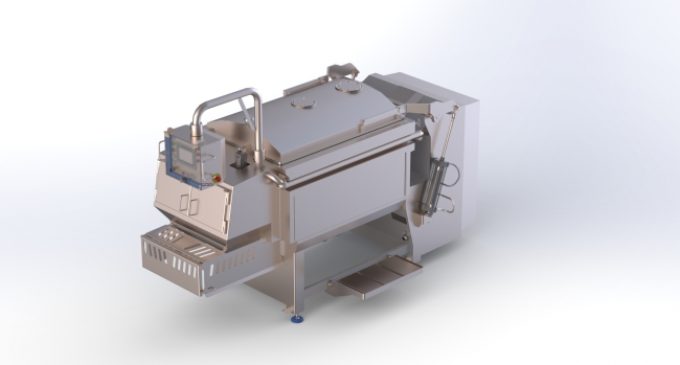

A system is now available from Interfood Technology which offers a wide range of cooking methods for many different applications, all from a single machine. Interfood is the sole supplier in the UK and Ireland of the Hot-Cook system from Alco Food Machines, an ingenious technology that can be used for various products, from soups, sauces and stews to fillings, ready meals, ground meat products, seafood concentrates, confectionery, vegetable preparations and ethnic foods.

It is based on a double-jacketed mixing vessel which is heated by steam or thermal oil, with temperatures of up to 210°C or 190°C achieved respectively. A unique energy-saving feature is the insulation of the vessel with ceramic/Rockwool materials and a complete weld to seal it. Other systems have considerably less or even no insulation, resulting in hot outer surfaces which not only waste energy but also present a potential burn risk to operatives. The paddles which move the product around the vessel are manufactured from a temperature-resistant and food-safe material, with spring-mounting to ensure gentle treatment of the product and to reduce wear and tear. Paddle speeds are adjustable depending on the product being cooked.

Available as an optional extra, the vessel’s lid is highly recommended as it retains the steam and the energy to reduce cooking times. Attention has been paid to ease of use, with the backward opening lid enabling loading from the mixer from either side of the vessel, thereby speeding up the whole process. Extracting the cooked product is also safe and easy via a thoughtfully designed knee-lever system and sealed doors which are opened and closed by compressed air.

A simple touchscreen allows recipes to be created, stored and amended, with easy retrieval of the recipes to ensure repeatability and therefore consistency in the end product.

Cooling is also available as an option: either water-based or through the injection of carbon dioxide and nitrogen. Additional options include automatic water dosing with flow and quantity control and the potential for bespoke construction to treat highly sensitive products.

The heat is directly transferred from the hot surfaces to the product, with improvements in yield achieved through the system’s fast searing and short cycle times.

Steve Naylor, Divisional Manager for Interfood’s Cooking & Cooling/Pasteurisation Division, comments: “The flexibility of the Hot-Cook system is highlighted by the range of cooking methods it offers, constantly mixing the product as it cooks. In addition to cooking, it can sear/sauté, blanch, directly inject steam and vacuum cook/cool. This is one of many options from our dedicated division, which also includes batch cooking, smoking and roasting, linear cooking, belt cooking, frying and spiral cooking.”