AutoCoding Systems and insignia Share Joint Success at FoodTech Qld

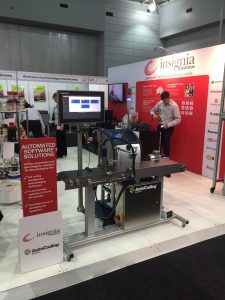

AutoCoding Systems have recently exhibited at the FoodTech Queensland show, sharing a stand with coding and labelling experts and Domino distributor, insignia.

AutoCoding Systems have recently exhibited at the FoodTech Queensland show, sharing a stand with coding and labelling experts and Domino distributor, insignia.

The company were demonstrating their coding and packaging verification solution which eliminates the risk of coding and packaging errors by automatically setting-up and controlling packaging line devices, removing human intervention which can sometimes result in costly errors being made.

At FoodTech the solution was used to set-up the Domino A420i inkjet printer as well as a SICK barcode scanner. The web-based AutoCoding application automatically deploys secure set-up and message data relating to one or more packaging line devices, irrespective of brand. The operator therefore can be confident that the coding information for the product is always correct. Inline scanning continually checks the packaging as the product runs down the line and should a rogue piece of packaging be detected, the line stops automatically to enable the operator to remove and take corrective action, thereby avoiding possible product recalls.

The resulting business benefits of the AutoCoding solution include increased reliability of line set-up, reduced job changeover time, reduced risk of human error and the ability to manage complex coding and packaging formats.

Many people who visited the insignia stand were introduced to the AutoCoding solution and both AutoCoding Systems and insignia are confident that this joint collaboration will lead to a number of mutually beneficial projects as visitors recognised the benefit of integrating a coding and packaging verification system on their packaging lines.

Having already installed the solution on multiple lines in major food manufacturers in Australia, AutoCoding Systems has recently opened their first office in Rowville, Victoria. They continue to build strong partner relationships with OEMs and System Integrators to support them as the company grows.