Digital 3D technology can now help businesses cut energy costs and carbon emissions

Businesses can now benefit from digital 3D technology to cut energy costs and reduce their carbon footprint using CyberPharm’s dynamic new 3D software.

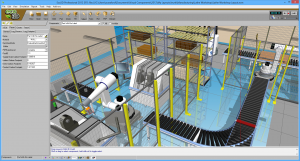

Businesses across the UK are set to benefit from digital 3D technology to develop their operations with the launch of virtual reality modelling by CyberPharm Ltd. Their sophisticated Eco3D Professional software package allows users to re-create their own business digitally using 3D modelling techniques to accurately calculate, and ultimately reduce, their carbon footprint and energy costs.

Businesses across the UK are set to benefit from digital 3D technology to develop their operations with the launch of virtual reality modelling by CyberPharm Ltd. Their sophisticated Eco3D Professional software package allows users to re-create their own business digitally using 3D modelling techniques to accurately calculate, and ultimately reduce, their carbon footprint and energy costs.

“One of the biggest advantages of this premium enterprise software solution is that it allows users to try out a wide range of alternative solutions to their problems before spending any money on costly real-life changes: to try before they buy, in effect.” says CyberPharm company director, Ian Aubrey.

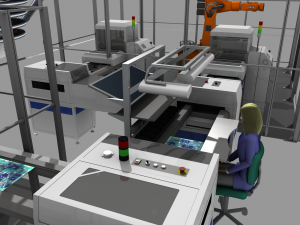

Aimed initially at factories and mass production lines, this advanced technology is newly available to businesses of all types via the new Eco3D software. Showcased at the recent Sustainability Live Conference where it was one of the main attractions, the software showed how 3D simulation is changing the face of carbon and energy analysis for business operations.

Using measurements, observations and data taken on site, the program creates a 3D replica of the business or organisation as it operates: a simulation model of the processes involved. That business could be in manufacturing, warehousing and logistics, automation and robotics, healthcare and public services – virtually any commercial business endeavour and many public service organisations.

This baseline simulation model reflects how the processes work currently – whether it be in a restaurant kitchen, commercial bakery or any other processing operation. Dynamic simulation provides the customer with the impression that they are actually in the facility with a bird’s eye or even walkthrough view of the system, as in a computer game. Analysis at this stage reveals any problems with rates of carbon emissions, energy wastage, logistical inefficiencies or whatever is being targeted.

CyberPharm provides advice, training and an extensive ‘component’ library to help businesses build these 3D models of their operations. This unique library is a large, ever-expanding resource detailing more than 60,000 energy-consuming products. All product information and energy consumption data is up to date, and allows users to input relevant details in order to build realistic models quickly, and with little technical knowledge. Analysis then reveals any problems with rates of carbon emissions, energy wastage and logistical inefficiencies.

Business can use the software to experiment with new processes, designs, input or components. This enables cost, productivity, energy and carbon benefits to be accurately calculated before any actual change or investment is made.

Proposed solutions are incorporated into a modified simulation then tested to see how they work in a particular business environment. In this way, ideas may be tried out in virtual reality, without risking the enormous costs of making any single one a reality before fully appreciating its impact.

“Even when the solution is set out in front of a business, they can still lose their way,” says Ian Aubrey, a CyberPharm Company Director, who has provided virtual reality solutions to major blue chip companies. “We are well aware of this, and so we also offer a ‘fresh eyes’ service to businesses using our software. In these cases, we come and look at their problem, and the possible solutions they’ve selected, and give our independent opinion. If needed, we can help businesses to understand and clarify the pros and cons of their choices, allowing them to make more informed decisions.”

CyberPharm offers a range of Eco3D software from Lite to Professional suited to a variety of clients from smaller businesses to large manufacturing concerns. In addition to the software, they also provide advice, training and an extensive ‘component’ library to help businesses build their 3D models.

Businesses helped by Eco3D products to make sustainable savings in their operations include G.H Sheldon, a North Western firm of industrial bakers providing morning goods to major supermarkets nationwide. CyberPharm helped them reduce the carbon footprint of their industrial lighting by 80% using 3D modelling. In Cheltenham, when celebrated restaurant Lumière decided on a major overhaul of their kitchen, they turned to CyberPharm for a 3D solution and increased their productive workspace by one third.

“The new plans resulted in a 33% increase in productive workspace,” says Jon Howe, Chef Patron at Lumière, who was able to try out a number of proposals in virtual reality saving on potentially costly mistakes – before opting for the final configuration. “Coupled with the extra capabilities of the new equipment, we have been able to keep improving the quality of our food, while saving energy and reducing our overheads. This prudency has helped us secure additional funding for the business and enter the Sunday Times list of top 100 UK restaurants in 37th place.”

“The new plans resulted in a 33% increase in productive workspace,” says Jon Howe, Chef Patron at Lumière, who was able to try out a number of proposals in virtual reality saving on potentially costly mistakes – before opting for the final configuration. “Coupled with the extra capabilities of the new equipment, we have been able to keep improving the quality of our food, while saving energy and reducing our overheads. This prudency has helped us secure additional funding for the business and enter the Sunday Times list of top 100 UK restaurants in 37th place.”

Ian Aubrey can see businesses of all kinds increasingly turning to this exciting development tool: “With the advance of modern processors, there’s an increased ability to simulate ever more complex scenarios. Extra speed means that many alternative layouts can be tried and tested before a single physical action is taken. This allows for more informed decisions to be taken and ensures a smoother build process avoiding planning mistakes and defects which can so easily snowball project deadlines and budgets.”

For further information please contact Louise Evans at Loop PR on 07891 242476.