Ibonhart – The Leader in Bread Slicing and Packaging Equipment

It is widely known that Ibonhart have been industry leaders in bread slicing and packaging equipment for over 30 years. More recently Ibonhart has refined its core products to provide user friendly, efficient and durable machines to excel in industrial environments for many years to come.

Ibonhart aims to meet all slicing and packaging needs for bakeries, ranging from sliced and bagged burger buns to large bloomer loaves. They currently have many machines installed in the UK and international exports are growing year on year, currently representing 80% of the company’s sales. This success story has not gone unnoticed and the UK government’s Trade and Investment web site refers to Ibonhart’s global success. Dealing internationally has also widened their product knowledge, due to the varying types of bread from all around the world; this allows new projects to be approached with great confidence.

Major Systems Investment

Since changing ownership 4 years ago the company has gone through a period of expansion and major systems investment. Managing Director Chris Barfe has a simple philosophy based firmly on customer satisfaction and product development.

Over the last 12 months, they have upgraded their business management software to a new system that links Design office to Parts, Purchasing and Accounts. This has allowed the company to modernise its production system, allowing them to shorten lead times for its customers.

In addition to this the Computer Aided Design system has been upgraded from a 2D package to a full 3D design suite, this is allows them to create drawings that are easy for suppliers to understand as well as giving them the ability to show customers a 3D view of a spare part they are enquiring about to ensure the supply of parts is accurate and efficient.

In addition to this the Computer Aided Design system has been upgraded from a 2D package to a full 3D design suite, this is allows them to create drawings that are easy for suppliers to understand as well as giving them the ability to show customers a 3D view of a spare part they are enquiring about to ensure the supply of parts is accurate and efficient.

This advanced 3D system has also benefited the company by allowing them to design and test new concepts on screen before putting them into production and testing. This has already resulted in a new dynamic inline in-feed which has helped achieve higher bagging speeds.

Ibonhart continually seeks to grow as a business; one way in which they have achieved growth is through employing and training young apprentices. Over the last four years new apprentices have been trained in both the mechanical and electrical departments of the business, this has allowed knowledge from experienced members of staff to be transferred to apprentices maintaining the vast expertise the company has, plus ensuring the latest techniques and products are utilised in production.

Advancements in Bakery Technology

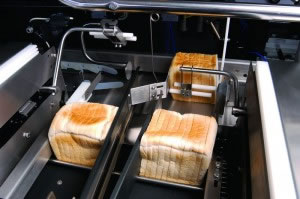

In addition to this input they have been working with suppliers to source innovative parts to bring their machines to the forefront of bakery technology. Advancements have been made in reducing air consumption for the bagging machines, Ibonhart has adopted in the design of all new packaging machines. Ibonhart’s bagging machinery by design is energy efficient due to their being multiple loaves inside of the bagging system during production. This is achieved by loaves being sliced, bagged and sealed at the same time as opposed to bagging and sealing one loaf in one sequence, which is not energy efficient.

![IbonhartIB360 Bagger Full System 0709[1]](http://www.fdbusiness.com/wp-content/uploads/2014/01/IbonhartIB360-Bagger-Full-System-07091-300x170.jpg) Ibonhart prides itself on the quality manufacturing of machines, constructed from parts manufactured in the UK. As well as sourcing precision engineered parts Ibonhart also have an in house machine and fabrication shops allowing them to make their own parts. Having in house facilities to manufacture has been the secret of its outstanding spare parts service which allows them to normally fulfil orders within 24 hours.

Ibonhart prides itself on the quality manufacturing of machines, constructed from parts manufactured in the UK. As well as sourcing precision engineered parts Ibonhart also have an in house machine and fabrication shops allowing them to make their own parts. Having in house facilities to manufacture has been the secret of its outstanding spare parts service which allows them to normally fulfil orders within 24 hours.

Research and development of new and existing technologies is key to Ibonhart’s success, their most recent development is the IB420 Band Slicer with fully automatic slice thickness adjustment. The slicer will be able to change slice thickness in one minute and slice with less than 0.5mm of variation. This fully automatic band slicer is undergoing final bakery testing and will be launched in early 2014 providing the market with the most advanced bread slicer to date.

The next stage in this development journey is to incorporate air sterilisation technology into the bagging machines to reduce the risk of bacteria entering the loaf as it is sliced and packaged. The system uses existing technology used in operating theatres to create a completely sterile atmosphere within the machine, as well as inflating the bag with sterile air. 2014 will see bakery trials take place and we are confident you will be reading a lot more about the company in coming months.

So whether you are a small bakery looking to take its first steps toward automation or a large plant bakery installing a new line or building a new plant Ibonhart can work from to design to installation through to spare parts and after sales servicing all based on the company’s customer focused philosophy.