Increase Throughput and Reduce Downtime With AutoCoding Systems’ Performance Monitoring Solution

Experienced systems integrator, AutoCoding Systems, has over 10 years’ experience in the FMCG sector offering automation solutions across packaging line operations. Their products comprise a proven range of modular applications, from entry level coding and packaging integrity solutions through to complete set-up and control of all packaging line devices, such as coders, barcode scanners, labellers, metal detectors, check weighers and vision solutions. The business benefits offered by AutoCoding Systems’ packaging line solutions include increased speed and reliability of line set-up, reduced job changeover time, reduced risk of human error, and the ability to manage packaging complexities. AutoCoding’s performance monitoring solution, facilitating the visualisation of manufacturing KPI data, is a natural extension of the AutoCoding product, but can also be used as a stand-alone solution.

Full visibility of the plant can be achieved via LED boards mounted above the equipment. This gives operators, maintenance staff and senior management the necessary tools to take corrective actions to ensure production is kept at optimum capacity.

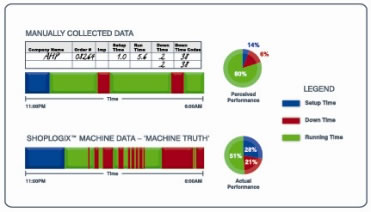

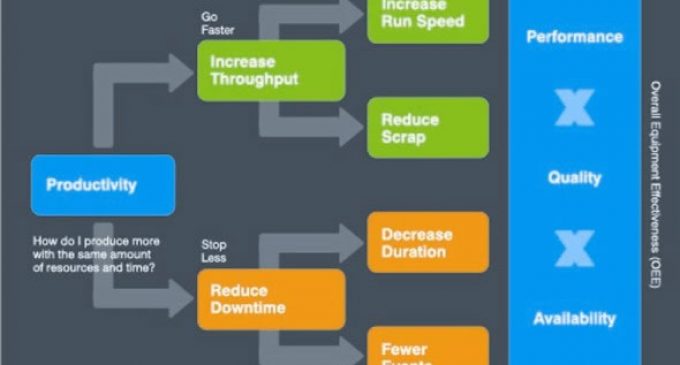

By identifying and evaluating where problems, performance limitations and constraints exist within processing and packaging applications, companies can minimise waste and increase throughput, whilst reducing operational costs to remain competitive. Manually collected data is often inaccurate and out of date. Automating the collection of production data ensures the data is accurate, reliable and of good quality. This, however, is just part of the solution. Having the ability to analyse, interpret and convert the data into meaningful and useful information is the second stage of the process. The AutoCoding solution provides highly professional reports to display accurate machine performance information. Whether tracking production counts, scrap rates, giveaway percentages, downtime reasons or shift variances etc, the graphical reports intuitively deliver the information needed to make immediate changes to effectively manage production and automatically alert management to potentially damaging situations.