Innovative Self-priming Pump Does Double Duty For Dairies

By Allan Bruun, Industry Manager, Dairy, Market Unit Food, Alfa Laval

Are you looking for a self-priming pump that improves energy efficiency and reduces noise levels, as well as meeting the latest hygienic design standards? Using airscrew technology, the Alfa Laval LKH Prime sets a new standard in self-priming pump technology.

Based on the Alfa Laval LKH premium range of centrifugal pumps the Alfa Laval LKH Prime is specifically constructed for pumping liquids containing entrained air, making it an excellent choice as a CIP return pump. The Alfa Laval LKH Prime is 40 percent more energy efficient and operates at noise levels 80 percent below conventional liquid-ring pumps. As all pumps in the LKH family, the Alfa Laval LKH Prime is EHEDG certified and authorized to carry the 3-A symbol.

Versatile and efficient, the Alfa Laval LKH Prime is therefore of interest to dairy owners and operators who are concerned with:

- Reducing energy consumption

- Improving the work environment

- Reducing installation costs.

Reducing Energy Consumption

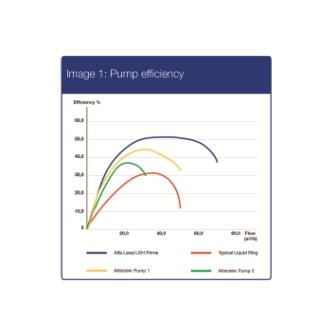

The hydraulic efficiency of the Alfa Laval LKH Prime reaches over 50% (Image 1). This means the Alfa Laval LKH Prime offers an added advantage over liquid-ring pumps, which typically reach efficiencies of approximately 30 percent. Its high efficiency is easily attainable at a wide flow range, which translates into substantial savings no matter the duty point.

The hydraulic efficiency of the Alfa Laval LKH Prime reaches over 50% (Image 1). This means the Alfa Laval LKH Prime offers an added advantage over liquid-ring pumps, which typically reach efficiencies of approximately 30 percent. Its high efficiency is easily attainable at a wide flow range, which translates into substantial savings no matter the duty point.

Improving the Work Environment

The Alfa Laval LKH Prime also contributes to a better work environment. It reduces the noise emission level by up to 80 percent compared to conventional liquid-ring pumps. With a noise level of a mere 74dBA, the Alfa Laval LKH Prime efficiently eliminates the need for these protective measures.

Reducing Installation Costs

While the Alfa Laval LKH Prime is primarily designed for CIP return duties, the hygienic design means it may also be used to pump dairy products. For instance, the Alfa Laval LKH Prime is a reliable pump for emptying milk tanks. Because of the pump’s ability to handle both CIP return liquid and dairy products, it is possible to eliminate the need for a separate liquid-ring pump.

The Alfa Laval LKH Prime combines the gentle product treatment and hygienic design of the LKH range with the liquid-ring principle. In many cases, this can reduce the number of pumps required for an installation from two to just a single pump.

Reducing the installation costs from two liquid-ring pumps to one Alfa Laval LKH Prime pump results in:

- Lower capital investment, one pump instead of two

- Lower piping, cabling and automation costs

- Lower spare parts and service costs.

Service is a key element of any Alfa Laval offering and the commonality of spares, including the shaft seal, in the LKH range translates into reduced spare parts inventory and fast maintenance.

Working Principle

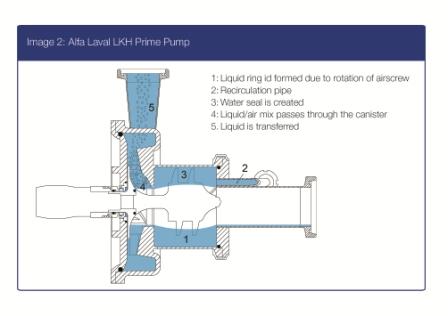

As the pump starts up, a liquid ring is formed in the pump head canister (image 2) and the recirculation pipe is filled (2), thereby achieving the initial prime. This liquid ring is formed in the space between the diameter of the inlet pipe, and the outer diameter of the offset canister housing the airscrew. The resultant liquid ring creates a water seal between the airscrew hub and the top of the canister (3).

An air column is created between the airscrew hub and the liquid ring (1). The air column is separated into air pockets by the airscrew and then forced into the impeller’s suction stage. Some of the priming liquid re-circulates over the recirculation pipe (2). Air is removed until the content is just a few percent and no pockets are generated. The pump then acts as a traditional centrifugal pump, transferring the liquid from the suction stage (4) through the discharge (5).

An air column is created between the airscrew hub and the liquid ring (1). The air column is separated into air pockets by the airscrew and then forced into the impeller’s suction stage. Some of the priming liquid re-circulates over the recirculation pipe (2). Air is removed until the content is just a few percent and no pockets are generated. The pump then acts as a traditional centrifugal pump, transferring the liquid from the suction stage (4) through the discharge (5).

When there is no air present, the canister and recirculation loop have no function and are completely filled with liquid. The liquid passes through the canister into the impeller’s suction stage. Here again, the pump acts as a traditional centrifugal pump, transferring the liquid through the discharge at a higher velocity and pressure.

Summary

The Alfa Laval LKH Prime Pump delivers:

The Alfa Laval LKH Prime Pump delivers:

- Reduced energy consumption

- Improved working environment

- Reduced installation cost

- And have spare parts commonality with the Alfa Laval LKH pump range making it easy to service.

Allan Bruun is Alfa Laval’s Dairy Industry Manager, responsible for the heat transfer and fluid handling business. Allan coordinates commercial and technical market intelligence between sales channels, dairies and central Alfa Laval functions seeking to optimize the customers’ processes and increase the competence level of the organization. Allan holds university degrees in mechanical and electrical engineering as well as business administration. Contact: allan.bruun@alfalaval.com.

About Alfa Laval

Alfa Laval’s worldwide organization works closely with customers in nearly 100 countries to help them stay ahead in the global arena. Alfa Laval is listed on Nasdaq OMX, and, in 2015, posted annual sales of about SEK 39.7 billion (approx.4.25 billion Euros). The company has about 17.500 employees.