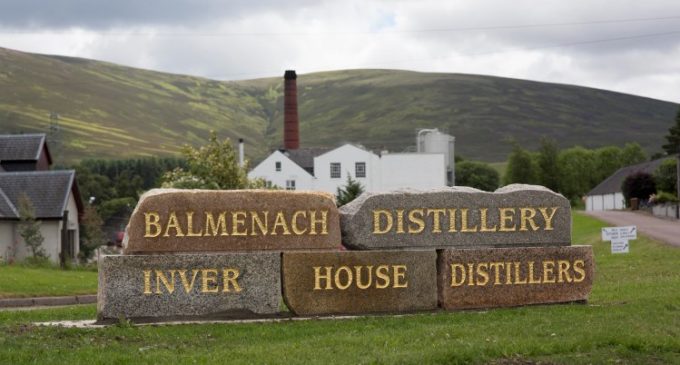

Inver House Distillers Drives Sustainability With £3 Million Biogas Investment at Balmenach

Balmenach, one of Speyside’s oldest whisky distilleries and the home of Caorunn Scottish Gin, is set to become one of Scotland’s greenest distilleries with the announcement that work has started on a £3 million biogas project to significantly reduce the site’s carbon footprint.

Inver House Distillers has commissioned a new anaerobic digestion system, which breaks down the co-products of whisky production using micro-organisms to produce clean, methane-rich biogas to power the site.

The new technology will integrate with Balmenach’s existing wood-pellet biomass boiler, and once complete, the combined system will generate enough renewable steam and electricity to meet 100 per cent of the Distillery’s energy requirements with a surplus of electrical energy supplied to the grid.

When operational in summer 2018, approximately 130 m3 of whisky co-products (pot ale and spent lees) will be processed to produce 2,000 m3 of biogas each day, feeding a combined heat and power engine which will supply 200kW of power and 230kW of heat.

Located near Grantown on Spey and one of Inver House Distillers’ five malt whisky plants, Balmenach is on track to produce 2 million litres of whisky for the blended Scotch market in 2018. The site is also the home of Caorunn, one of the fastest growing Scottish gin brands.

As well as the benefits of reduced emissions, improved energy efficiency and reduced operational costs, Balmenach’s use of these technologies will significantly reduce heavy goods vehicle movements from its remote location in the Spey Valley. The new system will also return clean water to the nearby burn, and nutrient rich bio-solids to the land for barley farming in the Speyside region.

Inver House Distillers’ Managing Director Martin Leonard comments: “Inver House Distillers was an early champion of green distilling in Scotland, and sustainability and consideration for the environmental impact at each of our sites is at the heart of our business strategy. With this new investment at Balmenach we are using the very latest technology to further that commitment, working with the best partners in the business to help us achieve our environmental goals. It’s an exciting step in our journey and one that we know is recognised and appreciated, not just by the communities surrounding our distilleries, but by the drinkers around the world who enjoy our premium spirits. We also hope this investment will demonstrate how low carbon manufacture and clean growth are achievable, regardless of the size, location or output of the production site.”

A team of specialist suppliers has been recruited by Inver House Distillers to deliver the new system:

Synergie Environ, the Glasgow-based low carbon energy engineering company, is project managing the installation at Balmenach through all feasibility, planning, permitting, procurement and construction phases. Managing Director Uisdean Fraser comments: “We have a long-established working relationship with Inver House Distillers and have worked hard with the management team over a number of years to help this exciting AD project come to fruition. I commend the Inver House management team for their forward thinking and vision and we are delighted that they chose us to lead the project from outline concept through all development stages to the current construction delivery phase. We believe the project will deliver a malt whisky distillery which is powered entirely from renewable energy sources with the on-site combination of biomass for the primary heat source and electricity from the CHP powered by biogas from the anaerobic digestion plant.”

Clearfleau, the specialist provider of on-site biogas plants for the food and drink industry, is working with Inver House to design and build the new system. Craig Chapman, CEO, of Clearfleau, says: “Clearfleau is delighted to be working with Inver House Distillers to further reduce carbon emissions at Balmenach Distillery. Once complete, the on-site biogas plant will provide a more sustainable solution for its co-products, supplying renewable energy that will help reduce the distillery’s power and other costs. Based on recent projects, Clearfleau is now developing a more modular plant design, for more remote sites and export projects.”

Balcas operates the existing biomass steam system at Balmenach, which uses brites wood pellets produced from home grown Highland timber local to the Distillery to produce zero carbon steam for the Balcas system. In the past 2 years since installation, it has enabled Balmenach to reduce its carbon footprint by 10,000 tonnes. Ian McCracken, Balcas Business Development Director, adds: “As a company committed to renewables, Balcas is proud to be associated with Inver House’s aspiration to stay at the forefront of the drive to deliver long term economic, environmental and social sustainability. Our 4MW biomass steam system is capable of meeting the demand previously met by a much larger traditional heavy fuel oil boiler. Over the same period this has displaced 3.1 million litres of imported oil while still making the same great tasting whisky and gin.”