Laboratory Informatics Easing the Process of Environmental Monitoring

Food and drinks manufacturers are required to run environmental monitoring programmes to maintain safe production environments. These are scheduled campaigns of testing for the presence of pathogens and indicator organisms both in plant and on equipment. The environmental sampling programme is normally documented and based on the international standard ISO 22000 Food Safety management systems, which are requirements for any organization in the food chain. In addition testing must conform to the appropriate ISO standard or equivalent test method.

Thermo Scientific SampleManager LIMS has extensive functionality for managing Environmental Monitoring programmes which is widely used in both Life Sciences and Food and Beverage manufacturing.

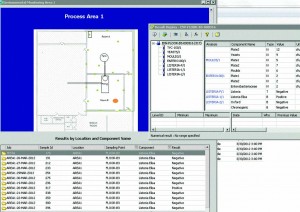

The main challenge for Environmental Monitoring is in managing the schedule and presenting the results. Data must be reviewed for trend analysis and to measure the efficacy of environmental monitoring programmes for both pathogens and non pathogens. Presence of indicator organisms can be a warning and allow appropriate action to be taken before there is a problem. SampleManager LIMS enables action and alert limits to be set and results compared with both. If there is a detection of a pathogen, or a possible related issue, the programs are flexible to allow for additional testing. If a problem is found, the data for surrounding locations can be viewed to identify the source of the problem. For example:

The following are key features in the SampleManager Environmental Monitoring function:

- Setting up an Annual Schedule or Programme for Environmental Monitoring, covering different frequencies and zones.

- Pre-Login of Samples and Alerts that the samples must be taken to ensure that all areas are monitored.

- Automatic Sample Login and Label generation.

- Sample Collection Sheets/Recording by sample collection point

- Scheduling of the Sample Incubation

- Recording of Results and Out of Specification Alerts.

- Presentation of Results on Equipment images, Site or Room Maps.

The figure above illustrates a schedule of samples to be taken for a plant, both in a process area and for plant equipment. Jobs, samples and test schedules are all set up to reflect the actual testing that needs to be performed. Samples are logged in according with a schedule or manually added where required.

The Environmental Results database builds up a comprehensive history of results over time to enable the manufacturer to pinpoint potential contamination sources in advance of production. The data can be used to show the effectiveness of cleaning and sanitation programmes and determine the frequency required.

Thermo Fisher Scientific and Orbis Labsystems are holding a seminar series to discuss how laboratory informatics can assist in areas such as HACCP, chemical and microbiological testing and Environmental Monitoring. Visit www.thermoscientific.com/foodsafetyseminars to register your free place.

Maria Allen, Orbis Labsystems, Ireland www.orb-is.com.