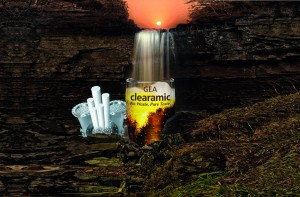

Waste-Free Beer Filtration with Ceramic Membranes

GEA Brewery Systems and GEA Westfalia Separator present clearamic  BeerFiltration at Brau Beviale 2014

BeerFiltration at Brau Beviale 2014

Breweries have been working with mechanical separation technology from GEA Westfalia Separator Group for over 100 years. Worldwide, every second litre of beer flows through GEA components. Sustainability is now a universal process criterion. The brewery industry too is intensively concerned with optimizing the consumption of natural resources and launching “green” products, which represent a high level of ecological responsibility. As well as changed legal constraints and image cultivation, cost concerns also play a substantial role here. The procurement, handling and disposal of filter aids have become e. g. a cost factor that increasingly impairs the profitability of breweries. At the same time, the consumer also still expects a brilliantly clear product of consistent quality. At Brau Beviale 2014 in Nuremberg GEA Westfalia Separator Group and GEA Brewery Systems present the perfect solution for this with its clearamic BeerFiltration.

No waste. Pure taste

The ceramic membranes form the centrepiece of this cross-flow filtration. The material is absolutely foodneutral and can be regenerated again at any time in the filtration system. The result: purest beer quality – brewed in a way that is sustainable and reduces costs. The process with the inert ceramic membranes makes filter aids such as kieselguhr entirely superfluous and is a pioneer for sustainable and gentle processes in beer production. The clearamic BeerFiltration can be flexibly adapted to the individual requirements in the brewing process and pays for itself after only a short time. Moreover, ceramic membranes have a very long service life for a minimum of ten years – this reduces the replacement costs to a minimum. Plus: ceramic membranes can be sterilized. Now, with clearamic BeerFiltration, breweries too have access to a proven GEA technology, as filtration with ceramic membranes has been successfully and reliably used in the area of wine and fruit juice for several years. clearamic BeerFiltration therefore represents a further important contribution from GEA to the unadulterated purity of the beer and to the protection of the environment.