Advetec Targets Food and Drink Manufacturers With Next Generation Organic Waste Digester

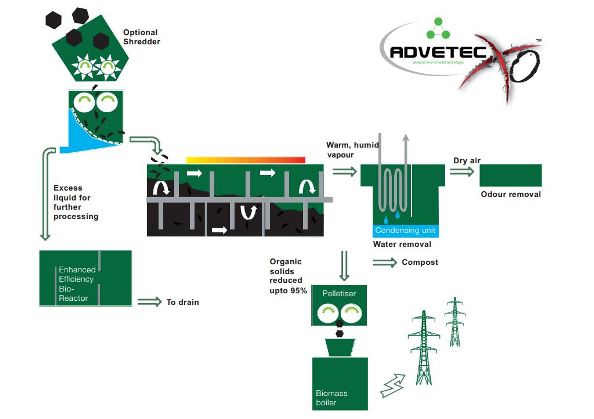

To reduce food processors costs, Advetec, a leading specialist in the treatment and reduction of solid and liquid organic waste, has launched the Advetec XO, an evolution of the company’s successful Bio-Thermic Digester (BTD) technology. The system is designed to rapidly reduce organic content within waste at source,cutting off-site transportation and processing costs and helping food manufacturing companies achieve zero waste to landfill.

Designed initially for industrial food and drink manufacturers who currently pay for organic waste disposal to be collected and processed off-site, the Advetec XO is a small footprint, fully contained on-site solution, delivering a 60% to 90% reduction in mass from mixed organic waste streams, with typical OPEX cost savings of 10% to 15% from day one.

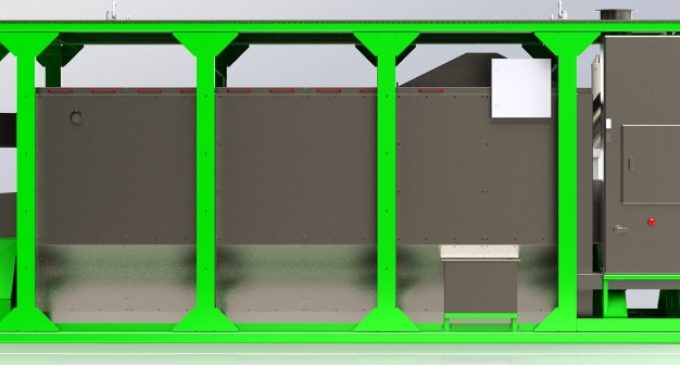

The completely re-engineered solution includes a range of improvements to both the mechanical integrity of the machine and internal processes, as well as the control software and remote monitoring systems. These ensure a more rugged and versatile machine, which is easier to optimise for individual customer requirements and changing waste stream composition at different production times.

Mechanically the new units incorporate a new exoskeleton to aid lifting and transportation, upgraded drive units with increased torque and changes to optimise the internal processes which move and mix waste as it passes through the machine. These improve performance capabilities with different waste streams, with overall efficiency gains of 10% over previous models.

Cycle times for waste digestion as material passes through the machine are now between 24 and 72 hours depending on density and composition of the waste. Importantly the Advetec XO is the only on-site solution which can handle non-organic waste contained within the organics. This gives operators the benefits and flexibility of not needing to sort or treat waste prior to processing in the Advetec XO system.

Cycle times for waste digestion as material passes through the machine are now between 24 and 72 hours depending on density and composition of the waste. Importantly the Advetec XO is the only on-site solution which can handle non-organic waste contained within the organics. This gives operators the benefits and flexibility of not needing to sort or treat waste prior to processing in the Advetec XO system.

Importantly, few infrastructure changes are required other than a power supply and a flat concrete base. In most cases operators can simply swap out existing skips or compactors and replace them with the new machine. No additional space is required and existing automated or manual material handling systems, previously used to load skips and compactors can be adopted.

A new software and sensor package with cloud-based data monitoring provides significantly improved control capabilities to further optimise performance and ensure the Advetec XO is operating at its peak capability. Status alerts covering key parameters enable engineers to predict issues early and make changes remotely, or visit the site. At the same time, it is now possible to look at performance trends and at the earliest signs of change take corrective actions.

The Advetec XO process uses a bespoke blend of thermophilic bacteria and nutrients to digest the organic content in waste utilising an exothermic reaction. This generates heat which sustains the high temperature environment required for the thermophilic bacteria, and ensures low energy cost. Waste is digested as it moves through the Advetec XO, producing water vapour that can be condensed or vented to atmosphere. The remaining output material is dry with a potentially a high calorific value. It may be suitable for use as RDF (Refuse Derived Fuel) or as a soil improver, depending on the input waste stream.

The Advetec XO is initially available in three unit sizes to handle different daily waste volumes from one to 13 cubic meters, and is scalable when machines are operated in parallel. This makes the solution equally attractive to organisations across the organic waste sector, food manufacturers of all sizes, but also hotels and restaurants, right through tomunicipal waste handlers and water utilities.

Advetec can offer machines through a Managed Service Agreement (MSA) fixed for 5 years which allows the customer to achieve OPEX savings from month one.

Machines are delivered pre-assembled and factory tested under simulated loadings following an analysis of the customer’s waste stream.