Ground Breaking Thermal Treatment Technology

Alflow Scandinavia, a leading flow component company in Denmark, is, in corporation with Emmepiemme srl, introducing a new ground breaking thermal treatment technology to their customers – Ohmic heating.

Ohmic heating is a type of thermal treatment in which the food acts as an electrical resistance, and thus is heated by passing electricity through it. Electrical energy is dissipated into heat, resulting in a rapid and uniform heating. Ohmic heating is also known as electrical resistance heating or Joule, and can be used in a variety of applications in the food industry.

We asked Jens Martin Andersen, Director at Alflow, how ohmic heating differs from conventional thermal treatment and what it is, that makes it a unique technology.

“Conventional thermal treatment, either in cans or other aseptic processing systems can cause significant damage to the quality of the product due to slow conduction and convection heat transfer. In contrast, ohmic heating volumetric heats the entire food mass, such that the resulting product is of much higher quality than by other methods.” says Jens Martin Andersen. “It is also possible to heat food with large particles, up to 25mm, which would be difficult to heat using conventional heat exchangers. In addition, the cleaning requirements are smaller than traditional heat exchangers due to reduced contamination at the interface between material and product. Worth mentioning is also the environmental issues: Ohmic heating only uses electricity. No emissions are produced at the point of use.”

Products Suitable For Ohmic Heating

Ohmic heating is especially useful for heating liquid foods containing large particles, such as soups, stews, sliced fruit in syrup, sauces and other heat-sensitive liquids. The technology is useful in the treatment of foods high in protein, which have a tendency to denature and coagulate when it is heat treated. Liquid eggs can be ohmic heated in a fraction of a second without coagulating. Juice can be treated to inactivate enzymes without affecting the taste. Dairy products such as cream cheese can also be UHT threated. Other possible applications of ohmic heating include blanching, thawing, fermentation, peeling, dehydration and extraction.

What about shelf life? Jens Martin Andersen says: “Because the treatment is a thermal process like conventional heating, the durability of ohmic processed foods are comparable to other sterile and aseptic processed products.”

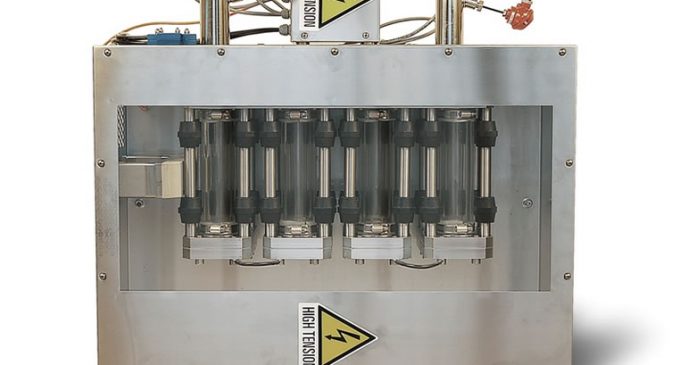

Commercial Equipment

Alflow Scandinavia is a company that services the chemical-, pharmaceutical- and food industry in flow equipment. Although the ohmic heating technology is interesting in its own, it does not matter much if commercial size equipment is not available. Jens Martin Andersen elaborates: “Emmepiemme in Italy supplies the equipment in commercial size and in the industrial scale test facilities in Italy we can, confidentially, conduct product evaluations on food safety, quality and durability. Emmepiemme and Alflow is also available for advice on product development.”

In Denmark, ohmic heating is used in the production of dairy products, including cream cheese. A number of plants worldwide produce soups and fruit using ohmic heating. In the US, ohmic heating was used to produce a product with coarser particles and low acidity, as well as pasteurized liquid egg. Generally, any product can be analyzed for the possibility of using ohmic heating.

“Because of our extensive knowledge in areas such as pumps, valves, pipes, fittings, tubing, stirrers and mixers, as well as related products in both synthetic materials and stainless steel, it is possible for us to guide our customers to the right solution,” Jens Martin Andersen adds. “It allows us to focus on our customer’s situation and not on our product portfolio.”