Kraft files patent for multi-purpose gum rollers

Kraft Foods (now Mondelez) has filed a patent for a chewing gum manufacturing process that can form the gum mass while cooling or heating at the same time.

“Typically, the process of making and packaging gum products is time-consuming and involves a significant amount of machinery,” said Kraft in its patent application.

“Typically, the process of making and packaging gum products is time-consuming and involves a significant amount of machinery,” said Kraft in its patent application.

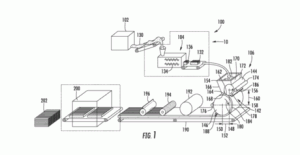

Equipment is normally needed for mixing, heating, extruding, forming, rolling, cutting and packaging. Kraft says its invention eliminates the need for a sizing-type extruder and can form and temperature manage the gum mass all at the rolling stage.

Conventional gum processing

In conventional gum processing equipment a sizing extruder is often used to force chewing gum through a small rectangular orifice. The product exiting the extruder is usually too thick and a series of sizing rollers are normally used to reduce the thickness to desired 2-6mm levels.

The rollers are typically cleaned by dusting with a powder agent which prevents gum sticking to the rollers. Conventional lines also need to cool the product to enable it to be packaged.

Kraft’s invention

Kraft’s invention uses a pair of rollers to size a gum mass, after the forming stage, into a continuously flat sheet with a uniform thickness 0.3 mm to 10 mm and a width of not less than 50 cm, through a gap between the rollers.

At the same time, the rollers can be heated or chilled to control heat transfer to the gum to give the appropriate width and thickness.

This process eliminates the need for powder dusting material used to clean the machine, which can reduce production downtime.

“As such, the clean up time for a change over, which was hours, 10 hours in some conventional rolling and scoring gum lines, can be reduced to minutes according to some embodiments of the present invention,” said Kraft in its application.