X-ray Detection With the Least False Positives

When it was launched in 2006, the Marel SensorX set a new standard in bone detection for poultry processors around the world. In the meantime Marel has not rested on its laurels but has continued to improve on a popular concept. The company’s drive to achieve the ultimate in quality, a wholly bone-free product, is perfectly in tune with today’s emphasis on food safety. Its latest step forward virtually eliminates false positives, an unwelcome distraction in bone detection.

The Marel SensorX x ray bone detection system has been a success story for many years now. Fully integrated software has become increasingly important in enhancing the accuracy and reliability of SensorX, both of which have now hit new heights.

The Marel SensorX x ray bone detection system has been a success story for many years now. Fully integrated software has become increasingly important in enhancing the accuracy and reliability of SensorX, both of which have now hit new heights.

Less Rework

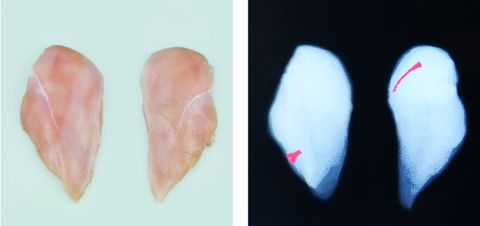

For poultry processors, the ideal x-ray detection machine should detect bone remnants and other contaminants with the very highest degree of accuracy. What processors don’t want is a machine which gives too many false positives. A false positive is material which is actually bone-free but which the machine handles and records as though it contained residual bone. In this situation, bone performance detection statistics, whilst looking impressive, will not reflect the true situation and could be misleading for departmental management. Marel’s latest Sensor X software not only reduces the incidence of false positives to an absolute industry minimum but also detects those difficult to see bone fragments more accurately. This means less rework and fewer inspectors, enhancing still further the machine’s already excellent performance.

Perfect Balance

The new software creates the perfect balance between a higher detection rate and a reduction in the number of false positives recorded. This balance is, however, a very thin line. It is no use trying to pick up the very smallest bits of bone, probably harmless to the consumer, if the percentage of bigger bones being detected is not high enough. Marel’s first goal was therefore to achieve the highest detection rate of “big” bone remnants in the market. Thorough and rigorous testing of the new SensorX software shows that this has been done.

When performing bone detection tests, false positives should always be included. If detection results are excellent, but the false positive rate is 30%, the machine is useless, as there is far too much rework to be done.

Saving Labour

A dual lane SensorX, working at full capacity, handles 240 pieces of meat per minute. Let’s assume the bone detection rate is 5% and the false positive rate is 6%. This would mean the rejection of 26 pieces of meat each minute. As an average operator can inspect 10 pieces per minute for residual bone, three would be needed to keep production running. If you can bring false positives down to 3%, the number of rejections drops to 19, necessitating just two inspectors; the savings in labour resulting from the new software are immediately obvious.

Food Safety

Consistently high levels of food safety are of vital importance in the poultry processing industry. The SensorX bone detection system is an efficient and cost effective way of detecting and removing bones and bone fragments from poultry products.

Marel Innova software collects data reliably, giving full traceability throughout the production process. It enables the real-time monitoring of key performance indicators such as throughput, capacity, quality, yield and the efficient use of labour. This valuable information helps ensure that products always meet the highest quality and food safety standards.

Market Leader

As of this moment, hundreds of SensorX systems are in operation with high-end poultry processors in some 40 countries around the world. Marel has become the market leader in bone detection for poultry; continuous improvement can only serve to strengthen this position still further.

For more information, visit www.marel.com/sensorX.