100% Accurate Beer Keg Barcode Reading

To ensure the fill quantity matches the stated weight, the Warsteiner brewery, located in Germany, weighs their kegs before and after the filling process. During the process, DataMan® barcode readers from Cognex are used to read the challenging barcodes that are affixed to the kegs. The solution for this was developed and implemented by BHV-Automation GmbH, together with Warsteiner’s own operational engineers.

The way to determine the content at Warsteiner depends on the type of packaging. For beer bottles, the filling level can be determined; for larger barrels (kegs), flow measurement is used and for the “Stichfass” (smaller keg), Warsteiner resorts to weighing. In the “Stichfass” plant, traceability of the kegs during the production process is currently provided by a combination of label printing, precision weighing and barcode reading. BHV-Automation GmbH (from Arnsberg, Germany) relies on Cognex DataMan 302X barcode readers for the challenging 2-D Data Matrix codes, which are robust enough to read the reflective codes on labels that are soaking wet and wrinkled. The DataMan 302X let BHV-Automation increase the application read rate from 92% to 100%! This eliminated the need for the complex manual re-weighing step in Warsteiner’s process.

An accurate in-depth look

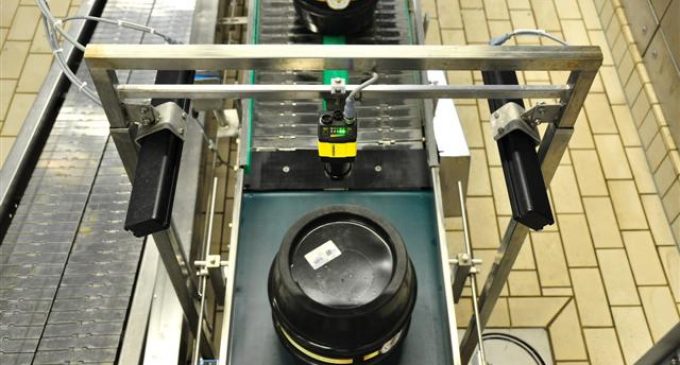

The actual content of the kegs is determined by Warsteiner using two weighing steps; one before filling and one afterwards. The difference between the overall weight and the weight of the packaging allows the exact fill content to be determined. For accurate traceability in the filling plant, each keg is given a serial number in the form of a Data Matrix code. A label printer applies the adhesive label with the Data Matrix code to the bottom of the keg before the first weighing. After this step, a Cognex DataMan 302X reads the freshly printed label. The code string is then sent via an RS-232 cable directly to the precision balance where the weighing process then takes place when the conveyor belt stops.

Reading the Data Matrix code is no easy task. The kegs come in 10, 15, 20, 30 and 50-liter variants, which mean that the distance from the barcode reader varies. The codes also vary in position as the kegs rotate as they move along the conveyor. However, these are not challenges for DataMan 302X, which can handle variations in depth of field and field of view.

Difficult-to-read codes

After the tare weight is measured, the keg continues through its filling process. The labels (and the Data Matrix codes) are subject to beer foaming over the keg and the cleaning water from the barrel washer unit, which make them even more difficult to read. There are often highly reflective water droplets on the code when the full keg is weighed, which would be a challenge for most barcode readers. However, the Cognex DataMan 302X is equipped with the powerful code reading algorithm, 2DMax+™ which has the ability to read damaged and difficult-to-read codes with ease. The DataMan 302X also is equipped with its own integrated light which is enough for the first reading station at Warsteiner. For the second weighing point, two linear lights in a 45° dark field arrangement provide the best possible contrast for reflective surfaces in a dark environment.

Barcode readers for a safe and secure process

If the quantity filled is within the given tolerance range, the keg is transported further for storage. Incorrectly filled barrels are removed, emptied, cleaned and refilled. The two weighing stations with Cognex barcode were a complete success for Warsteiner, saving them time and money. Because the reading station recognizes 100% of the Data Matrix codes applied to the kegs, manual re-weighing becomes unnecessary. The DataMan 302X is one of the main factors in the success of this solution. It was designed to cope with the most demanding applications with hard-to-read codes on clocked or high-speed lines. The 2DMax+ algorithm gives it a crucial advantage over competitive products. In addition, the liquid lens autofocus gives the DataMan maximum flexibility in obtaining the desired depth of field. Furthermore, the controllable and field replaceable red lighting allows the DataMan to be configured to provide the best possible lighting for any application. This unique design enables the DataMan 302X to achieve the highest read rates, even under the most difficult conditions.