Brooklyn Brewery Chooses Fresh Floor Finish

After abandoning plans to build a new $70 million state-of-the-art plant at the Brooklyn Navy Yard in nearby Staten Island, N.Y., world-famous craft brewers, Brooklyn Brewery, sought major re-development work at their long standing home in Brooklyn’s Williamsburg neighbourhood, including upgrades to floor coating systems located in the brewery’s main production halls. Bucking the trend for dairy brick, the brewer opted for close to 8,000 sq. ft. of Flowcrete’s urethane cement for major upgrade works to its manufacturing facility located at the former matzo plant where it has operated since 1996.

The brewery, which originally opened its doors to a dozen visitors each Friday evening in the late nineties now nets around 3,000 to 4,000 visitors each weekend, including New Yorkers and visitors from across the globe on a pilgrimage to taste the company’s distinct brands and flavours.

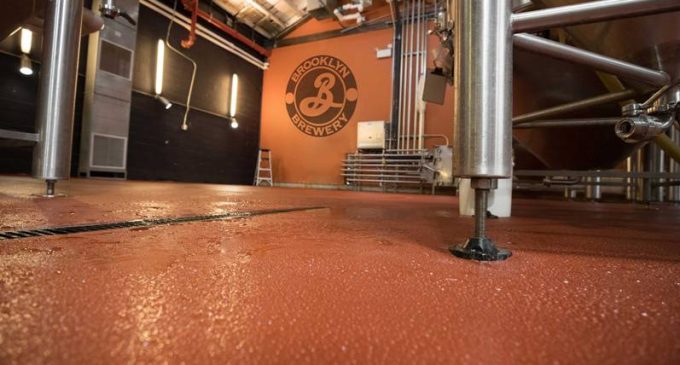

Flowcrete’s durable and slip-resistant, Flowfresh SR cementitious urethane was selected for installation in the brewery’s main production hall with a subsequent topcoat of 100% solids Flowcoat CR for additional chemical resistance in the face of punishing brewing conditions.

It takes a lot of heat to turn malt, hops, water and yeast into a beer ready for tasting. The heat helps unlock the enzymes and contributes to alcohol level. The malt is mixed at temperatures as high as 200 degrees – filling the plant with a sweet-smelling aroma for employees and visitors to the site taking the weekly tours. During brewing, the mixture varies between boiling and 65 degrees.

Flowfresh material is highly durable offering excellent thermal cycling and thermal shock resistance. This makes the material ideal for installation in areas subject to extremely hot temperatures or those that may be exposed to intermittent hot spillage or hot water wash down processes.

Unlike dairy brick, Flowfresh cementitious urethane systems are installed in a seamless application, meaning no joint or grout lines, which can become susceptible to damage and cracking and once penetrated offer a ripe spot to harbour dirt, dust and other bacteria.

Seamless Flooring Systems Inc. in Somerdale, N.J, completed the installation work over seven consecutive weekends. The installation was challenging for crews as much of the equipment remained in-situ throughout the install. As such, highly skilled applicators working low down and often in tight spaces were required.

“A lot of labor was involved, with crews applying a degreaser prior to pressure washing, followed by treatment with a diamond grinder to remove contaminants in the cement, much of it worn down to expose aggregate,” says Chris McDermott, Vice President of Seamless Flooring Systems Inc. “With the forklift traffic and dropping kegs, brewing is one of the most abusive industries we deal with. Although cementitious urethane isn’t a permanent fix, with correct care and maintenance can be serviceable for upwards of 15 years.”

There are a lot of urethane cements available on the market but they’re not all the same. An antimicrobial additive – Polygiene® – is standard in Flowcrete’s Flowfresh systems, which have been installed in countless food and beverage manufacturing facilities across the world for more than 30 years. “I won’t put epoxy down,” McDermott warns.

Flowfresh material is certified by HACCP International as food-grade for use in both wet and dry processing and production areas. This international standard recognises both the safety and suitability of this product to meet the variety of challenges found in the food and beverage manufacturing industry.

Brian Campbell, Flowcrete Americas’ Regional Manager for the East Coast, says: “The Brooklyn Brewery project is a testament to both the quality of the Flowfresh materials alongside the skill and talent of the installation team. I look forward to visiting Williamsburg to check in on how the floor is holding out and perhaps have a tipple at the same time.”

For more information on the installation of Flowfresh SR and Flowcoat CR at Brooklyn brewery, you canview a video of the project on You Tube.