Fast, Flexible, Accurate – Ishida’s ‘Hungry Monster’

The success of the preferred supplier partnership between Ishida Europe and Tulip, one of the UK’s leading food processing companies, is ideally demonstrated by the latest installation of Ishida equipment at Tulip’s factory in Ruskington, Lincolnshire, where a bespoke line is handling 2.7 tonnes of frozen cocktail sausages every hour. With each cocktail sausage weighing approximately 10g, this equates to an impressive 270,000 sausages per hour.

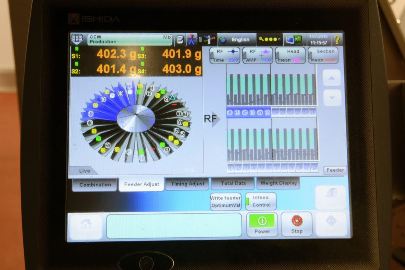

The Ishida solution comprises both a 24 head and a 14 head multihead weigher from the company’s top-of-the-range RV series, the 24 head feeding a thermoformer while the 14 head is operating in conjunction with a vertical bagmaker. Ishida also supplied the elaborate feed system, the gantry for the weighers and a bespoke tray filling system, together with a DACS-W-012 checkweigher for final weight control.

Key to the success of the new line is its ability to manage the high volume throughput with minimal product giveaway, and also its flexibility in coping with a variety of packing and production requirements. The line has been designed to feed the sausages either to the 24 head weigher, which packs them into thermoformed trays for many of the UK’s leading retailers, or to the 14 head model which packs them into bags, mainly for the foodservice sector.

Key to the success of the new line is its ability to manage the high volume throughput with minimal product giveaway, and also its flexibility in coping with a variety of packing and production requirements. The line has been designed to feed the sausages either to the 24 head weigher, which packs them into thermoformed trays for many of the UK’s leading retailers, or to the 14 head model which packs them into bags, mainly for the foodservice sector.

After manufacture and frying, the sausages enter a spiral freezer where they emerge at the top and are fed into the packing operation. It is particularly vital to ensure that production continues uninterrupted, and the system therefore has the ability to divert product for temporary storage – WIP (Work In Progress) as it is termed – while work is carried out on the line, for example a changeover of pack formats.

Product is then fed back to the weighing and packing system to return the packing operation to full speed.

In addition, the line is linked to another processing and packing line in the factory so that product on this line can be easily switched over to cope with high demand – for example, sales of certain products can increase by anything up to 20% when a sunny weekend has been forecast.

In addition, the line is linked to another processing and packing line in the factory so that product on this line can be easily switched over to cope with high demand – for example, sales of certain products can increase by anything up to 20% when a sunny weekend has been forecast.

Centralised control of the line ensures these changes can be carried out quickly and efficiently.

The 24 head weigher is split into 4 sections with six weigh heads dedicated to each quarter of the weigher, in order to handle the sausages as efficiently as possible and maximise throughput. The weighed cocktail sausages then pass through a 4×4 configuration filling system above the thermoformer that fills 16 trays at a time at 12 cycles per minute.

Typical speeds are 192 packs per minute for a 220g tray, 180 for a 345g tray and 150 for the 480g size. The 14 head weigher is operating at around 50 bags per minute for 4kg packs.

With each sausage weighing approximately 10g, pinpoint accuracy is vital and this is an area where the Ishida weighers perform consistently well, according to Tulip’s Project Engineering Manager Rob Hunt, who was responsible for the entire installation.

With each sausage weighing approximately 10g, pinpoint accuracy is vital and this is an area where the Ishida weighers perform consistently well, according to Tulip’s Project Engineering Manager Rob Hunt, who was responsible for the entire installation.

“We needed a solution that combined accuracy and speed and the Ishida weighers are consistently delivering minimal giveaway at an impressive consistency,” he comments. “They are also very reliable, easy to use and our operators love them. We refer to this line as the ‘hungry monster’ as it is able to handle nearly anything we throw at it in terms of production throughput.”

The factory operates two eight-hour shifts, five days a week, with a comprehensive clean of the line every night in accordance with Tulip’s stringent hygiene standards.

The hygienic waterproof design of the Ishida RV weighers is certified to IP-69K specification. Features include upgraded seals and gaskets, angled surfaces for rapid wash down and water run off (ensuring faster drying times) and reduced crevices in bushings and hoppers, which help to eliminate bacteria traps. As a result, the RV weighers installed at Tulip offer maximum hygiene while minimising downtime for cleaning.

The new line was part of a major investment project co-ordinated by Rob Hunt. This involved an extension to the existing building, which was built, fitted out and the line installed as a self-contained unit before the internal wall (which had been the original exterior wall) was removed to join up the new area with the rest of the factory.

The new line was part of a major investment project co-ordinated by Rob Hunt. This involved an extension to the existing building, which was built, fitted out and the line installed as a self-contained unit before the internal wall (which had been the original exterior wall) was removed to join up the new area with the rest of the factory.

“Our close working relationship with Ishida and our other suppliers was crucial to the success of the project,” Rob continues. “We were very clear about what was required and we worked as a team to ensure this could be achieved. In this way, any potential issues or problems could be identified, dealt with and solved early in the process so that they did not slow down or affect the progress of the job.”

The result was a project that was delivered on time and on budget.

The new line at the Ruskington site joins a variety of Ishida equipment which has been installed there over the years including five multihead weighers, three QX-1100 tray sealers and nine DACS-W checkweighers.