Getting to Know the Power of a New Choice

A new ‘game changing’ adhesive dispensing system program named ChoiceTM was just recently launched by Valco Melton. Unlike other “kit solutions” the Choice program brings true innovation to all users of hot melt application systems. The ChoiceTM is an airless, high performance, all-electric system that dramatically reduces adhesive usage with the capability to apply a limitless option of perfect adhesive patterns at the working speed needed by the customer. This system pays for itself with hard savings in as little as 3-4 months.

Pneumatic technology is old school. Although it has been around for a while, it was never accepted by some industries because of its inefficiencies. Because these systems operate using compressed air, they are costly to manufacture and corrosive to the components that use them. Electric valves operate with near 100% efficiency. The air flowing into the cylinder that operates the piston pump can contain moisture, debris and oil residue. Eventually this may cause the valve to lose effectiveness and consistency. This problem requires an additional process of replacing small parts, modification of adhesive and more to try and get the system back to its optimum performance – ultimately meaning downtime, spare parts and additional adhesive investment. By eliminating all compressed air usage, there is no possibility of contaminants to cause the valve to wear out.

Pneumatic technology is old school. Although it has been around for a while, it was never accepted by some industries because of its inefficiencies. Because these systems operate using compressed air, they are costly to manufacture and corrosive to the components that use them. Electric valves operate with near 100% efficiency. The air flowing into the cylinder that operates the piston pump can contain moisture, debris and oil residue. Eventually this may cause the valve to lose effectiveness and consistency. This problem requires an additional process of replacing small parts, modification of adhesive and more to try and get the system back to its optimum performance – ultimately meaning downtime, spare parts and additional adhesive investment. By eliminating all compressed air usage, there is no possibility of contaminants to cause the valve to wear out.

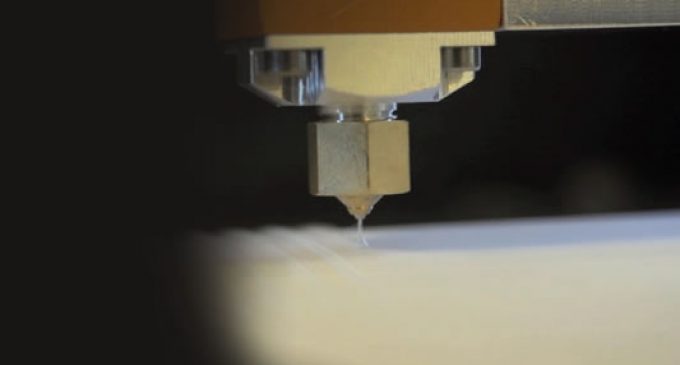

![ValcoMeltonChoice System[1]](http://www.fdbusiness.com/wp-content/uploads/2013/07/ValcoMeltonChoice-System1-300x238.jpg) The Choice System can be configured for pattern or stitch with only the press of a button. This option allows the operator to choose the size of the glue dots and the gap between dots without complicated calculation or programming tasks. Valco Melton’s new EcoStitchTM applies the desired stitch pattern based on what is best and required by the end user. The EcoStitch feature can reduce your adhesive usage by up to 75% while allowing you to operate at lower pressures and larger nozzle orifices. With hard savings on adhesive and parts usage, safer operating parameters and less downtime associated with nozzle plugging, the Choice can be yours.

The Choice System can be configured for pattern or stitch with only the press of a button. This option allows the operator to choose the size of the glue dots and the gap between dots without complicated calculation or programming tasks. Valco Melton’s new EcoStitchTM applies the desired stitch pattern based on what is best and required by the end user. The EcoStitch feature can reduce your adhesive usage by up to 75% while allowing you to operate at lower pressures and larger nozzle orifices. With hard savings on adhesive and parts usage, safer operating parameters and less downtime associated with nozzle plugging, the Choice can be yours.

These are just a few of the immediate advantages that the industry’s forefront leaders are seeing following implementation. Learn more about how the Choice System can start bringing savings to your line today here: http://delivr.com/24zbt.