Macsa ID UK Underlines Commitment to Industry 4.0 Readiness

Further underlining its commitment to Industry 4.0 readiness for improved manufacturing efficiencies, Macsa ID UK Ltd – a newly established division of Barcelona-based laser coding, marking and scoring equipment manufacturer, Macsa ID – is highlighting the benefits of its integra modular software for easy integration of its machines with other key devices on the production line.

Many companies implement Industry 4.0 projects with a common objective to integrate business processes through cloud technologies and improve synergies across the company. In many cases, big data analytics, preventative maintenance and remote maintenance by specialists are targeted as the first step in the process.

These Industry 4.0 projects necessitate the development of products that cover all aspects of maintenance, administration capability, fault-free operation and data collection.

Product development and engineering processes at Macsa ID UK are orientated to produce smart coding and marking equipment. The company’s high performance systems have the ability to communicate and are capable of producing multiple data. For example, the power used in any cycle of operation and the working temperature help to determine the amount of power used to code or a mark a product.

The key enablers for the data collection from Macsa ID UK coding and marking systems are sensors and microcontrollers embedded within the electronics, with each one monitoring specific conditions. This information can be shared in real-time or collected and shared at defined intervals.

In the future everything will have a digital identity and connectivity, enabling users to identify, track and communicate with these specific objects.

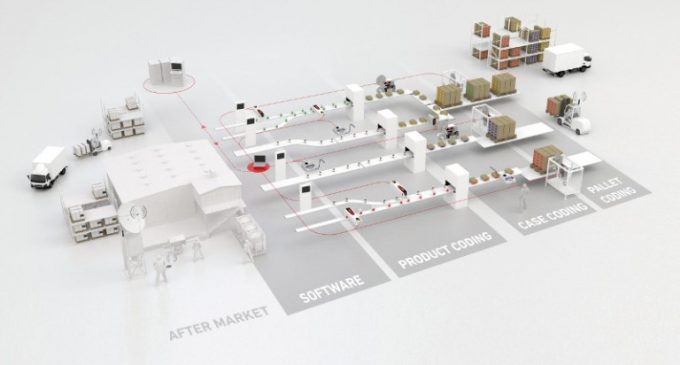

Macsa ID UK has developed its integra modular software for easy integration of its coding and marking products with other equipment on the production line. The highly functional software enables data to be collected from all devices and can then be used to drive efficiency and help anticipate adverse performance.

Integra software collects data from both internal and external sources for decision making, to improve manufacturing processes and operations, give the capability from data flow to analytics. It allows customers to integrate equipment in the production line, as well as connect it to other devices and to central databases.

It allows real time tracking of production goods and end user alerts when they do not fulfil pre-defined quality standards.

Based on operational data, users can define more appropriate operation processes in terms of speed, scale and costs. Plus new components or processes can be developed or redesigned to avoid specific failures and eliminate unused features.

Through continuous monitoring, users can determine when maintenance will be needed saving on routine maintenance costs and avoiding failures.

Macsa ID UK offers several versions of its Integra software. These include integra-connect for integrating different equipment; integra-optima for centralised management of the coding, marking and identification process; integra-vision to manage and check both the production and coding processes and integra-efficiency for managing the efficiency of the production line, while also optimising it.

For further information visit www.macsa.com.