Make the Most of Your Raw Product – Minimize Give-away and Maximize Quality

Here’s a thought – how much extra food can we produce if we optimize the production processes all the way from the harvest to the end consumer’s table? And how can we improve and enhance our businesses if we are smart and precise in every step of the process?

By handling food with care and intelligence, Cabinplant can help you get the most out of every piece of meat, fish, vegetable or the food product you are making. Cabinplant has the technology to precisely measure, cut, trim, weigh and package any food product on the market.

Weighing and Packing Solutions

Speed, flexibility and accuracy are key parameters to optimize your production economy. Cabinplant has a multitude of optional features which enable you to produce sticky and fragile products with accurate results at high speed on our weighing machines.

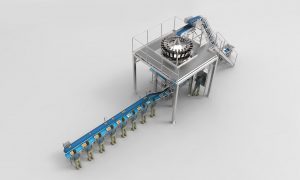

One of the recent inventions from the company is the fully automatic multi batcher. It is suitable for weighing and batching of large portions at high speed and handles portion sizes of up to 30 kg of meat or meat by-products. The accurate weighing of batch sizes reduces give-away significantly compared to other systems and improves your return on investment.

The Cabinplant multi batcher is tailor-made based on product size and batch size according to customer request and available either as a stand-alone unit for automatic or manual bagging, box packing or filling into thermoformed packages, or as part of a complete packing line.

Weighing and Packing of Sausages

Another recent development within their weighing and packing solutions is a sausage depositor. It is a fully automatic solution for alignment of portions of sausages (or similar products) in trays. The depositor is designed to operate together with a multihead weighing machine and must be installed directly above the thermoforming/tray sealing machine.

The weighed-out portions fed by the multihead weigher are dropped into a vibrating unit, where each portion is aligned. After alignment, the portions are gently discharged into trays. The sausage depositor is designed to handle various formats and multiple product layers and to minimize give-away.

From Stand-alone Machinery to Turn-key Projects

Designing food production equipment is often a question of combining various existing technologies in new and innovative ways. That is one of the core skills of Cabinplant – to meet your requirements, while applying everything they know about automation, robotics and mechanical engineering.

The people of Cabinplant use their skills and long market expertise in designing a production line which is tailor-made to your needs and specifications. Altogether, Cabinplant’s ability to provide precision weighing of all kinds of products and development of food processing technology puts you in a very strong position.