Packo Pumps rewrites the standard for product pumps together with the industry

The vegetable and potato processing industry has changed profoundly. By strain refinement the potatoes that have to be pumped became much larger. The free passage in the product pumps has to follow this trend. Also the volumes that have to be pumped increased enormously and loss by damage is yet barely tolerated. The pumps that are used in this market segment up till now score, widely considered, inadequately in that area and the demand for better performing pumps resounds more emphatically through recent years. That was also the reason for Packo Pumps to begin the re-design from zero. The result is the VPCP pump that rewrites the prevailing norm. The VPCP pump has been developed in collaboration with the industry. It has been tested extensively and proven radically incomparable. Packo Pumps challenges you.

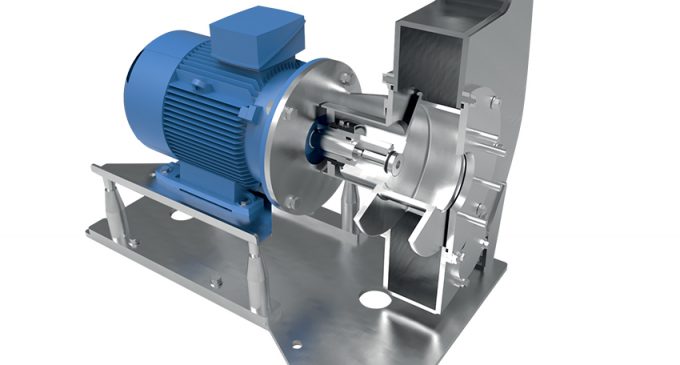

Larger stainless steel pump casing

First the needs and trends of the industry were identified and converted into design requirements. The full geometry of both the impeller and the pump casing was studied via CFD and redesigned with a view to the largest possible free passage and minimal product damage in the widest possible working area. The result of months of CFD study and several practice tests is a range of four pump types with a significantly larger pump casing but with the same mounting dimensions as the VDKM pumps (except for type 150-400).

The principle remains a complete stainless steel pump, like the Packo standard dictates. Cleanability, corrosion resistance and more strict hygiene requirements, after all, are gaining importance.

Vane replaces impellers

A second intervention replaces the traditional channel impeller with an impeller with a single vane, which was specially developed by Packo for this pump series. The design of the vane plays a key role in the performances of the new VPCP pump. It also leaves a large free passage and is designed to keep product damaging minimal. Research showed that by omitting the channel geometry the product damage is minimal over a much wider area (flow and speed). A typical single channel impeller only shows a low product damage in a small zone around the BEP (Best Efficiency Point).

Test results prove 250% less product damage

In order to evaluate and compare the product damage objectively Packo Pumps developed a test method that produces a dimensionless damage figure. The damage figures are both a quantitative (% of products being damaged by the pump) as qualitative (how serious is the damage?) weighing of the damage. The new VPCP pump scores a damage figure of 9.5. In comparison, the known VDKM pump registered a damage figure of 25.5. We can therefore state that the product damage in the new generation VPCP pumps is 2.5 times smaller than in the VDKM pumps. Also pumps with conventional 1-channel impellers were subjected to the same test. No single pump scored a damage figure below 14. We can therefore confidently say that the VPCP pump series sets a new benchmark in terms of product damage.

Sustainable construction

In addition to the pump hydraulics, also the structure of the pump itself was taken in hand. The versions with larger motor capacities were shortened 75mm, which makes the pump not only more compact, but also makes the shaft much stiffer and eventually benefits the life time of the mechanical seal. Because field tests confirmed the durability of a single seal, the new generation of pumps will not be equipped with an oil bath around the shaft seal anymore.

Target market of the VPCP pump series

The Packo VPCP pump range is designed for pumping potatoes, vegetables, like broccoli, cauliflower, sprouts, etc. The VPCP pump can e.g. be used in Belgian fries process lines and for the transport of vegetables to the blanching lines.

Because the pump has the same dimensions as the known VDKM pump

series it is easily interchangeable.

Overall, the VPCP pump is characterized by:

New benchmark in minimal product damage in a wide area (flow and speed),

One of the largest free passages in product pumps on the market,

4 types: 125-315, 150-400, 200-500 and 250-630,

Steeper pump curve: easier to adjust and less risk of clogging the system.

Pump completely in electropolished stainless steel,

Compact monobloc construction, dimensionally shorter than the VDKM pump series,

Duplex stub shaft allows a quick and easy disassembly of the vane,

Standard IEC normalized motor,

Only two standardized (EN 12756) mechanical seal diameters (3 to 45kW and from 5 to 10 inch pump),

Sledge construction by which the pump can be easily slid backwards while the pump casing remains in the piping system,

Available with vertical or horizontal outlet,

In accordance with European food contact regulation EC 1935/2004,

Pump is equipped with large manhole cover and drain,

Same dimensions as the known VDKM pump, which make them easily interchangeable.

Packo Pumps, the specialist in stainless steel centrifugal pumps!

Packo Pumps is originally researcher, designer and manufacturer of sustainable and innovative industrial pumps. Our pumps rank among the best of the world when it comes to hygiene and cleanability.

Packo pumps are also an important link in the reliability and the improvement of the energy efficiency of our customers. To this end, we develop and constantly improve more pumps tailored to our clients, for the most diverse applications.

Our slogan “We Optimize Your Flow” reflects our ambition to be a valued partner in the optimization of your business processes.

Need more information? Contact bart.vanbastelaere@packo.com or visit our new website www.packopumps.com.