BrauBeviale 2018: Sustainable Solutions For Every Inch of Your Beverage Application

Regardless of what beverage type you produce, a reliable operation is paramount to the success of your application. Unplanned downtime caused by components that were never intended for a beverage processing line can be avoided if you choose a supplier with the experience and knowledge to specify your operation properly.

At Brau Beviale 2018 Rexnord will present some of the latest innovations. The first innovation is Rexnord’s patented Magnetflex® Curve System. We developed the innovation as we understand that conveying glass containers, cans and PET bottles around curves can be challenging as chains can fall out of place, be noisy, hard to clean and consume large amounts of energy. These problems are resolved with this solution, which combines magnets and ultra low friction (ULF™) material to reduce downtime, noise and energy consumption.

The Magnetflex Curve System integrates magnets into the plastic curve track on the upper part to cover almost the complete base of the curve. This unique design keeps steel chains and plastic chains with steel pins securely in place as it goes around the curve. The magnetic pull stays constant throughout the life of the Magnetflex System, helping to make the system virtually maintenance free. When the system is stopped for sanitation or maintenance, the chain is easily lifted from the track to be cleaned and inspected.

The Magnetflex Curve System integrates magnets into the plastic curve track on the upper part to cover almost the complete base of the curve. This unique design keeps steel chains and plastic chains with steel pins securely in place as it goes around the curve. The magnetic pull stays constant throughout the life of the Magnetflex System, helping to make the system virtually maintenance free. When the system is stopped for sanitation or maintenance, the chain is easily lifted from the track to be cleaned and inspected.

New ART™ Dynamic Chain

The other innovation that Rexnord is presenting at Brau Beviale 2018, is the new ART™ Dynamic Chain, which has the ability to create multiple behaviors –zero back line pressure, rotation, acceleration, deceleration, low pressure accumulation, metering, and sequencing–in one single conveyor design, unlike others that require multiple conveyors to perform those behaviors.

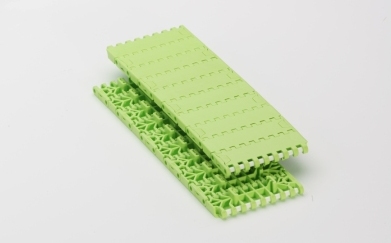

Rexnord Dry-PT Material

Next to these two new innovations, we will highlight our Rexnord Dry-PT Material. This material will help set a sustainable conveyor standard for the future. Our Dry-PT Material has proven to be the first plastic chain material to provide the required low friction against PET on a constant level over time, where other plastic chain materials always show a permanent increase of friction level after hours of running. It has been developed specifically for high-speed conveying applications for PET containers where the goal is to run without or with minimal external lubrication.

Please come visit our booth (HALL 7A, STAND 425) and meet Rexnord’s skilled Engineers who will help you understand our complete product portfolio and support you to find the perfect conveying solutions for your application. For further information visti www.rexnord.com.